- Optimize storage by utilizing vertical space, like tall shelving units, to maximize capacity.

- Implement a FIFO system to reduce waste and prevent inventory spoilage or obsolescence.

- Ensure proper labeling and organization for efficient inventory management and streamlined picking processes.

- Conduct regular inventory audits to maintain accurate stock levels and prevent stockouts or overstock situations.

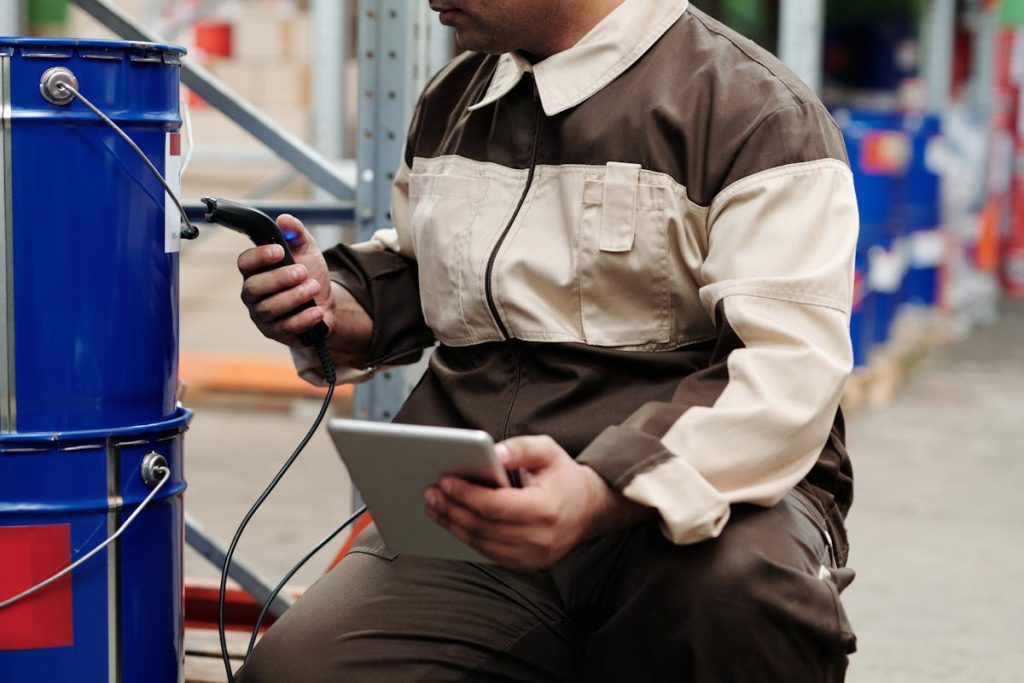

- Invest in technology, such as barcode scanning and WMS, to enhance productivity and improve inventory accuracy.

Efficient storage practices are essential for businesses of all sizes. Whether you are a small online retailer or a large manufacturing company, having a well-organized and optimized storage system can make a significant impact on your bottom line. This blog will discuss the best practices for storing goods that can help businesses improve their operations and maximize their efficiency.

Utilize Vertical Space

One of the most effective ways to optimize storage space is by utilizing vertical space. Investing in tall shelving units or installing mezzanine floors can help businesses make the most out of their warehouse or storage area. By stacking goods vertically, companies can maximize their storage capacity without needing to expand their physical footprint.

Implement FIFO (First In, First Out) System

To prevent inventory spoilage and obsolescence, it is important for businesses to implement a FIFO system. This means that goods should be stored and picked in the order they were received, ensuring that older items are used or sold first. By following this practice, businesses can reduce waste and minimize the risk of holding onto the obsolete stock.

Labeling and Organization

Proper labeling and organization are critical components of an efficient storage system. Businesses should clearly label shelves, bins, and pallets to quickly identify where each item is located. Additionally, grouping similar items together can streamline the picking process and reduce the time spent searching for specific products.

Regular Inventory Audits

Conducting regular inventory audits is crucial for maintaining accurate stock levels and preventing stockouts or overstock situations. By regularly counting and reconciling inventory levels, businesses can identify discrepancies early on and take corrective actions to avoid costly mistakes.

Professional Assistance

For businesses that may not have the resources or expertise to optimize their storage space, seeking professional assistance can be highly beneficial. A reputable 3PL (third-party logistics) provider can offer customized solutions and expertise in warehouse management to help businesses maximize their storage capacity and improve overall efficiency.

They’ll have a 3PL warehouse manager who can oversee the entire process and make recommendations for improving storage and inventory management practices. This can free up time and resources for businesses to focus on other essential aspects of their operations.

Invest in Technology

Modern technology can significantly enhance a business’s storage operations. By investing in technology solutions, companies can increase productivity, reduce errors, and ultimately improve customer satisfaction. Here are four types of technology that can be beneficial for storage and inventory management:

Barcode Scanning

Barcode scanning systems allow businesses to quickly and accurately track inventory levels, reduce manual data entry errors, and improve order fulfillment processes. Additionally, barcodes can be used for location tracking and picking confirmation, making them valuable tools for efficient storage operations.

RFID (Radio Frequency Identification)

Similar to barcode scanning, RFID technology uses radio frequency signals to track and manage inventory. Compared to barcodes that need line-of-sight scanning, RFID tags can be read from a distance without the need for physical contact. This makes them ideal for tracking and managing high-volume or bulk items.

Warehouse Management Software (WMS)

A WMS is a software system designed specifically for managing warehouse operations. It can help businesses automate processes such as order fulfillment, inventory tracking, and stock replenishment. With real-time visibility into inventory levels and locations, businesses using WMS can make data-driven decisions to improve efficiency and accuracy.

Inventory Management Software

Inventory management software allows businesses to track inventory levels, monitor stock movements, and generate reports on demand. It can also integrate with other business systems, such as accounting software, for streamlined financial management. With automated alerts for low or excess stock levels, businesses can stay on top of inventory needs and avoid costly issues like stockouts or overstocking.

These are just a few examples of technologies and systems that can significantly benefit inventory management in a warehouse setting. With the advancements in technology, businesses have more options than ever before to streamline and optimize their warehouse operations.

Efficient storage practices are crucial for businesses aiming to enhance their operational efficiency and reduce costs. By utilizing vertical space, implementing the FIFO system, ensuring proper labeling and organization, conducting regular inventory audits, seeking professional assistance, and investing in modern technology, businesses can significantly improve their storage and inventory management. Adopting these best practices not only maximizes storage capacity but also enhances productivity, minimizes waste, and boosts customer satisfaction, ultimately contributing to a healthier bottom line.